ISO Non metallic Inclusion Inspection Standards:

(1) ISO 4967:2013

ISO 4967:2013 “Determination of Non metallic Inclusion Content in Steel – Standard Rating Chart Microscopic Inspection Method” replaces ISO 4967-1998, but its content has only undergone minimal changes, and its inspection method and rating chart have not changed. The 1988 version of this standard has been equivalently adopted by GB/T 10561-2005.

(2) ISO 9341-1996

ISO 9341-1996 “Optics and optical instruments – Determination of incompleteness of inclusions and surface defects in fixed contact lenses” introduces the methods and steps for detecting inclusions and surface defects using fixed contact lenses. It was discontinued in 2006 and replaced by ISO 18369.3:2006 “Optics and optical instruments – Contact lenses – Part 3: Test methods”.

American non-metallic inclusion inspection standards:

(1) ASTM B796-2014

ASTM B796-2014 “Test Method for Non metallic Inclusion Content in Powder Forged Parts”, replacing ASTM B796-2007, is suitable for the metallographic determination of non-metallic inclusion levels in powder forged parts, requiring 100% porosity detection in the core area of the sample. If there are gaps, it is difficult to distinguish the residual pores from oxide inclusions.

(2) ASTM E45-2013

ASTM E45-2013 “Test Method for Determining Inclusion Content in Steel” is a widely used non-metallic inclusion inspection standard, which includes four macroscopic inspection methods and five microscopic inspection methods (manual and image analysis) to describe the content of inclusions in steel and the reporting method of inspection results. The five microscopic inspection methods include: A method (worst field of view method), B method (length method), C method (oxide and silicate method) D method (low inclusion content method) and E method (SAM rating method); ASTM E45 has established a series of standard reference maps (JK maps and SAE maps) to describe the characteristics (size, type, and quantity) of typical inclusions. The SAE map can be found in the recommended J422 operating procedure in the SAE manual; The spectra of Method A (worst field of view), Method D (low inclusion content), and Method E (SAM rating) were developed based on the JK spectra, while Method C (oxide and silicate methods) used the SAE spectra.

(3) ASTM E1122-1996

ASTM E1122-1996 “Standard Test Method for Determining JK Inclusion Level by Automatic Image Analysis” was discontinued in 2006 and has been integrated into the newly revised ASTM E45-2013, Methods A and D.

(4) ASTM E1245-2003 (2008)

ASTM E1245-2003 (2008) “Standard Test Method for Determination of Inclusion or Second Phase Structure Content in Metals by Automated Image Analysis.”. Suitable for using automatic image method to evaluate the content of endogenous inclusions and second phase microstructure in metals. Due to the scattered and unpredictable distribution of exogenous inclusions, this standard is not applicable for evaluating exogenous inclusions in steel or other metals.

(5) ASTM E2142-2008

ASTM E2142-2008 “Test Method for Evaluation and Classification of Inclusions in Steel by Scanning Electron Microscopy”. According to the procedures specified in ASTM E45 and ASTM E1245, the quantitative evaluation of inclusion content in steel is carried out using a scanning electron microscope; The determination of the quantity, size, and morphology distribution of inclusions is classified according to chemical methods.

(6) ASTM E2283-2008 (2014)

As is well known, the failure of mechanical components such as gears and bearings is often caused by the presence of a large amount of non-metallic oxide inclusions. Microscopic observation of failed components often traces the presence of inclusions. The prediction of fatigue life of failed components cannot be reasonably evaluated by inclusion inspection standards such as ASTM E45, ASTM E1122, and ASTM E1245. ASTM E2283-2008 (2014) “Code for Analysis of Extreme Values of Non metallic Inclusions and Other Microstructure Characteristics in Steel” emerged under these conditions. This standard creates a standardized method using extreme value analysis, which is related to component life and inclusion size distribution. Like ASTM E1245-2003 (2008), this standard is not applicable for the evaluation of exogenous inclusions in steel and other metals.

German non-metallic inclusion inspection standards:

(1) DIN 50602-1985

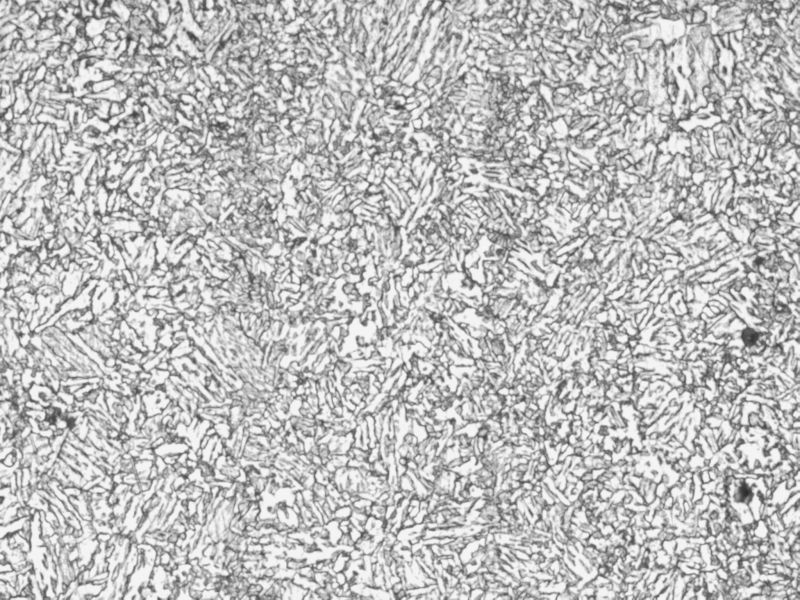

DIN 50602-1985 “Microscopic examination method for evaluating non-metallic inclusion content in high-quality steel using metallographic diagrams” is widely used as a microscopic examination method standard for non-metallic inclusion content in high-quality steel, referenced by more than 120 product standards. This standard divides non-metallic inclusions in steel into four categories: SS type, OA type, OS type, and OG type, corresponding to sulfide inclusions, oxide inclusions, silicate inclusions, and spherical oxide inclusions, respectively. These 4 types of inclusions are divided into 9 levels, represented by 0-8. Adjacent levels result in a difference of twice the inclusion area. The sampling quantity is one furnace or a batch of materials, and usually there are no less than 6 samples. Three graphs are used to evaluate the level of inclusions. At the same level, sulfide inclusions (SS type) and spherical oxide inclusions (OG type) are divided into two series based on differences in inclusion width and thickness, while oxide inclusions (OA type) and silicate inclusions (OS type) are divided into three series. In each type of inclusion and each series, corresponding length ranges of inclusions are provided, and a table of length ranges corresponding to inclusions of different widths is also provided. There are two evaluation methods for DIN 50602-1985: M method and K method. The M-method is to record the highest level of inclusions on the entire inspected area, and after separately evaluating and recording various inclusions in the selected sample, calculate the arithmetic mean. The K-method calculates inclusions from a specified level, so the standard specifically applies to special steels. Therefore, the lowest level of evaluation depends on the steel smelting process, material usage, and product size. The number after K represents the minimum number of levels used in the evaluation using the graph. For example, K4 refers to the frequency of occurrence of inclusion levels starting from level 4. The level of inclusions varies, and their hazard coefficients also vary. Multiplying the frequency by the coefficient yields the total number of inclusions in a single sample. The total number of inclusions in all samples in the sample group is added up, and the result is converted to 1000 mm2, which is the total index of inclusions. K4 is commonly used, and when calculating, OS type inclusions are generally classified as OA. At present, this standard has been invalidated and there is no new revised standard to replace it. Its technical committee recommends using DIN EN 10247-2007 for the inspection of non-metallic inclusion content in steel.

(2) DIN EN 10247-2007

DIN EN 10247-2007 “Microscopic examination of non-metallic inclusion content in steel using standard images” is a metallographic examination method standard for non-metallic inclusion content in steel developed based on the trial version of DIN V ENV 10247-1998 “Microscopic examination of non-metallic inclusion content in steel using standard images”. This standard divides non-metallic inclusions in steel into six basic types, represented by EA, EB, EC, ED, EF, and AD, The evaluation methods are divided into P method (worst inclusion method), M method (worst field of view method), and K method (average field of view method), among which M method and K method are consistent with DIN 50602

The description in 1985 is basically consistent, and many newly formulated product standards in Europe have begun to reference this standard.

(3) Other

The testing standards related to the inspection of non-metallic inclusions also include: SEP 1570-1971 “Microscopic Inspection Method for Non metallic Inclusion Content Rating Charts of Special Steel”, SEP 1570-1971 (Supplement) “Microscopic Inspection Method for Non metallic Inclusion Content Rating Charts of Fine and Long Special Steel”, and SEP 1572-1971 “Microscopic Inspection Method for Sulfide Content Rating Charts of Free Cutting Steel”

Inspection standards for non-metallic inclusions in other countries:

JIS G 0555:2003 “Microscopic test method for non-metallic inclusions in steel” (Japanese standard).

It is a standard microscopic test method for determining non-metallic inclusions in rolled or forged steel products (with a compression ratio of at least 3). The actual inspection methods for inclusions in this standard are divided into A method, B method, and point calculation microscopic inspection method. The A method and B method are completely consistent with the representation method in ISO 4967:2013, and the point calculation method represents the purity of steel by the percentage of the area occupied by inclusions. This standard is widely used to evaluate the suitability of steel for application, but due to the subjective influence of experimenters, it is difficult to achieve satisfactory results, so a large number of samples and predictions are required for application.

BS 7926-1998 (R2014) “Quantitative micrographic method for determining the percentage content of non-metallic inclusions in steel” (British standard),

Two microscopic photography methods for determining the content of non-metallic inclusions in cast steel were described in detail. The area fraction of non-metallic inclusions in cast steel specimens was specified, and the percentage range of non-metallic inclusions in the four melting and refining methods used by steel foundries was also specified.

New Gapower Metal is a professional Free cutting steel manufacturer. The main products include 1212 1213 1214 1215 1140 1144 12l13 12l14,12l15 11SMn30 etc. Customers could find all the type tube that they needed.

Post time: Dec-25-2023