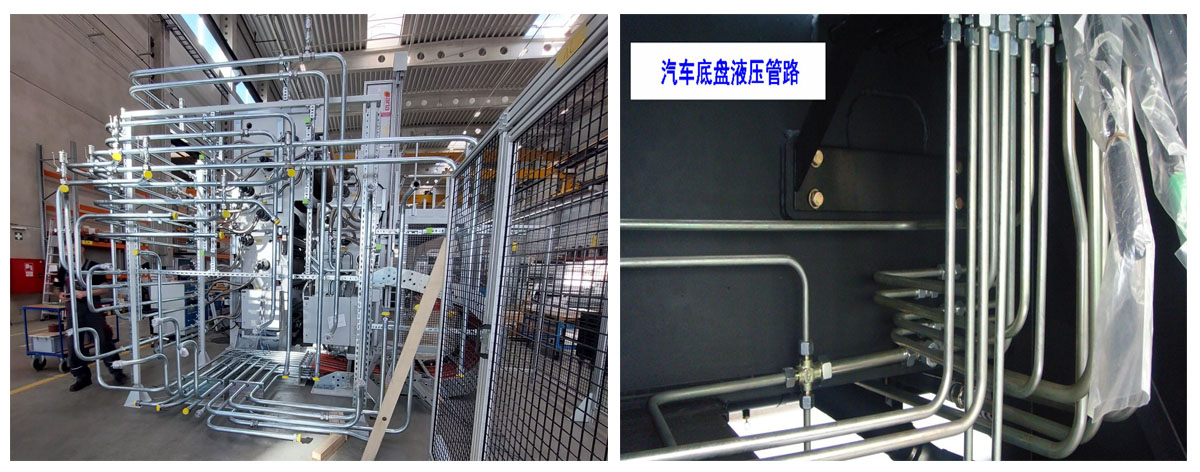

DIN2391 series zinc plated hydraulic seamless steel pipes are mainly used for hydraulic systems, and users with high requirements for rust and corrosion prevention of the outer wall of the steel pipes. It is also particularly suitable for precision hydraulic seamless steel pipes used in any hydraulic system, excavators, road machinery, engineering machinery, sanitation vehicles, ceramic machinery, and brick making machines High precision galvanized hydraulic seamless steel pipes for environmental protection equipment and sanitation vehicles.

DIN2391 series galvanized white zinc hydraulic seamless steel pipes are made from DIN high-precision precision drawn bright precision seamless steel pipes as galvanized steel pipes. The outer walls of the steel pipes are treated with cold galvanizing, and both ends are covered with dust prevention treatment.

Main features: high precision, good smoothness, no oxide layer on the inner and outer walls of the steel pipe after heat treatment, good cleanliness of the inner wall, high pressure resistance of the steel pipe, no deformation during cold bending, and no cracks during expansion and flattening. It can handle various complex deformations and mechanical processing. Steel pipe color: white zinc, colored zinc (yellow zinc), with good rust and corrosion resistance on the outer wall of the steel pipe.

The steel pipes used in hydraulic systems are mainly stainless steel seamless pipes and ordinary seamless pipes. Although stainless steel seamless pipes have excellent mechanical properties, they have not been widely used due to their high price and low accuracy. Although ordinary seamless steel pipes are commonly used, their mechanical properties are poor and their accuracy is low. Before use, they usually undergo a series of welding, trial assembly, acid washing, alkali washing, water washing, long-term oil flushing, and leakage testing. The process is complex, time-consuming, and unreliable, and the residue inside the pipes is always not thoroughly removed, becoming a major hidden danger for the entire hydraulic system to malfunction at any time. According to statistics, 70% of faults in hydraulic systems are caused by this reason.

Main use: Steel pipes for hydraulic systems, users with high requirements for rust and corrosion prevention of the outer wall of the steel pipes.

The products are widely used in hydraulic system piping, injection molding machines, hydraulic presses, shoe making machinery, hydraulic equipment, high-pressure oil pipes, sleeve (steel pipe) joint connections, rubber machinery, forging machinery, die-casting machines, engineering machinery, environmental sanitation vehicles, automotive industry, shipbuilding industry, metal processing, * *, diesel engines, internal combustion engines, air compressors, construction machinery, shipbuilding equipment (CCS certification), metallurgical equipment, agricultural and forestry machinery, etc, And establish a good reputation in various industries.

Post time: Aug-18-2023