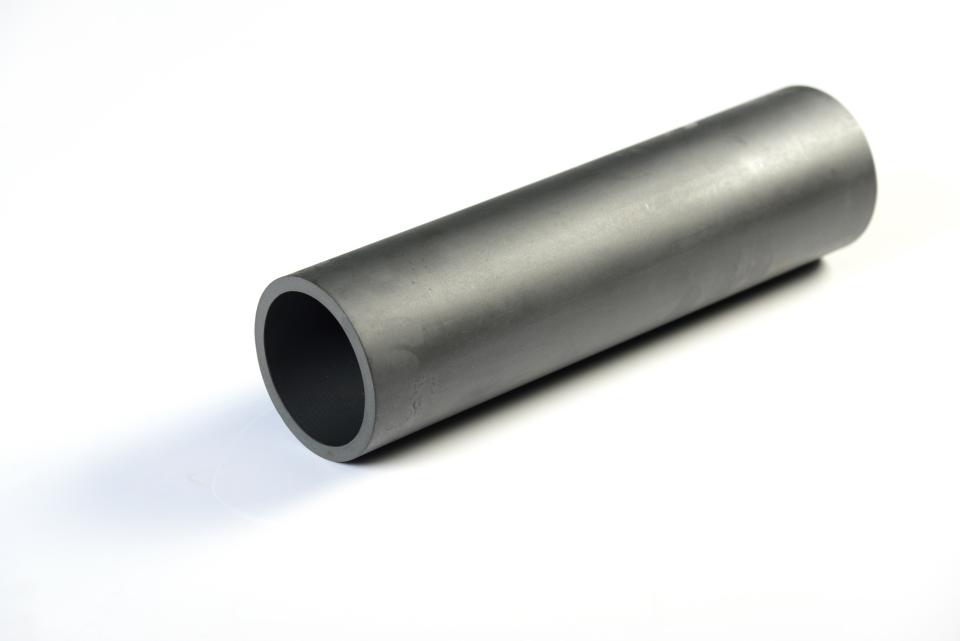

According to the requirements of the rules on the frame, the structure of the racing car must include two roll cage with support, front bulkhead with support system and buffer structure, and side anti-collision structure, that is, the main ring, front ring, roll cage slant support and its support structure, side anti-collision structure, front bulkhead, and front bulkhead support system. All the frame units can transfer the load of the driver restraint system to the basic structure. The frame unit refers to the shortest, uncut, and continuous individual pipe fittings. One of the functions of the frame is to withstand various loads from inside and outside the vehicle, but the mechanical properties of various materials vary greatly, making it difficult for designers and judges to determine whether the frame’s load-bearing capacity meets the standards. Alloy steel is an iron carbon alloy formed by adding an appropriate amount of one or more alloying elements to ordinary carbon steel. By adding different elements and using different processing techniques, special properties such as high strength, high toughness, wear resistance, corrosion resistance, low temperature resistance, high temperature resistance, and no magnetism can be obtained. And our protagonist’s full name is 30CrMo Pipe, also known as 4130 Steel Pipe. It has high strength and toughness, good hardenability, and a hardenability diameter of 15-70mm in oil. The steel has good thermal strength, ranging from 500 ˚ Below C, it has sufficient high-temperature strength and good welding performance.

4130 domestic grade 30CrMo is an alloy steel containing chromium and molybdenum, with a tensile strength generally above 750MPa. The most commonly seen on the market are bars and thick plates. Thin walled 4130 steel pipe will be used to make Bicycle frame,. This is a detachable steel pipe assembly. It is made of cold drawn seamless carbon steel pipes bent and installed one by one according to the contour of the interior of the carriage. If you remove the body shell, you will see a metal cage made of several steel pipes. Therefore, Hongkongers people also call it “roll cage”. With this precious diamond armor, even if the vehicle rolls a few times and the exterior of the vehicle is unbearable, the racers inside will still be safe and sound. The steel pipe material and twist resistance used for the anti roll frame are determined by the weight of the vehicle body, and generally need to be able to withstand an impact of more than twice the weight of the vehicle body. As the road surface of the track race is relatively flat, there is almost no gap. In contrast, if the Rallying on the mountain road and the cross-country race in the wild overturn, the body damage will be greater. Therefore, the strength of roll cage for rally racing and cross-country racing is higher, and the structure of pipe fittings is denser. The professionally installed anti roll frame can not only cope with unexpected situations, but also enhance the strength and anti twist of the vehicle body. For example, by connecting several welding positions of the roll cage to the front and rear shock absorber seats, even if the vehicle frequently jumps, a portion of the impact force from the ground will be dispersed onto the roll cage, which provides protection for the vehicle body.

4130 was mainly used in the aircraft industry, but in the early to mid-1950s, when it entered the racing chassis structure, the situation began to change. Just like the aviation industry, the use of 4130 as the main chassis structural material in racing has been gradually developed over the years. At that time, many Racing driver questioned the welding ability of 4130, because TIG welding is a very new technology, and most manufacturers use brazing to weld this material. It was not until 1953 that Boeing Aircraft Company recorded and began TIG welding of its 4130 structure. It is impossible to determine the chassis of the first 4130 car, but it is likely that it was first used in car racing, such as SCCA car, top fuel car, IndyCar or Formula One.

By the mid-1950s, many cars made of 4130 were competing in multiple levels of competition recognized by SCCA. In 1953, Forest Edwards manufactured the Edwards/Blue Speical using a dilapidated 51 year Morris sedan and 4130. Charles Hall will drive his “little excavator” to win the SCCA H-class modified Pacific Coast Championship, which uses 1.25 inches × A trapezoidal frame made of 0.030 inch 4130.

Dragmaster Dart: Dodd Martin and Jim Nelson, along with their Dragmaster Dart, founded Dragmaster Company in Carlsbad, California in approximately 1959 or 1960. They are at the forefront of racing technology and have won the “Best Design” in the NHRA national competition. Within less than a year of opening, Dragmaster began producing a chassis called “Dart”, which comes in two materials: 4130 and mild steel.

In 1965, the Brawner Hawk, a rear engine made from 4130, made its debut and was driven by Mario Andretti. Brawner Hawk was built by the legendary mechanic Clint Browner and his disciple Jim McKee at the time. It was designed based on Copper Climax, the first rear engine car to enter the 500th mile starting line in India in 1961, driven by two time Formula One champion Jack Brabham. That year, under Mario’s driving, Braun Hawk achieved great success. At the Husserl Grand Prix held at the Indianapolis Circuit Park, Mario won the first five places in four qualifying competitions, one pole position and five top five places, as well as his first victory in USAC. He also won the 1965 season championship of USAC and the 1965 Indianapolis’ 500 ‘Stark Wetzel Rookie of the Year.

In the late 1960s and early 1970s, Dennis Klingman and Wyatt Swaim of Lincoln Electric went to Europe to teach Formula One auto manufacturers how to TIG weld 4130 tubes instead of brazing. In the late 1970s, 4130 will gradually enter other forms of competition. Around 1971, Jerry Weeks Baker manufactured a new cage using 4130 on his Austin Healy Sprite car and competed in SCCA recognized events. At that time, SCCA’s rulebook allowed the use of 4130, but it was not recommended because welding was difficult. Jerry later built a 4130 mini car for Don Edmonds to participate in the race recognized by the American Automobile Association (USAC). Around 1975, USAC stipulated that 4130 could be used as long as it was in a normalized state.

By the late 1970s, many certification agencies began to require the use of 4130 manufactured roll cage in the highest level of competition. On December 12, 1978, SFI stipulated that all top-level fuel vehicle chassis must be made of 4130 material. SFI is a non-profit organization aimed at publishing and managing standards for professional/performance automotive and racing equipment. By 1984, SFI also stipulated that funny cars must be manufactured with 4130.

Post time: Jul-18-2023