Seamless steel pipes are divided into two categories: hot-rolled and cold-rolled (drawn) seamless steel pipes.

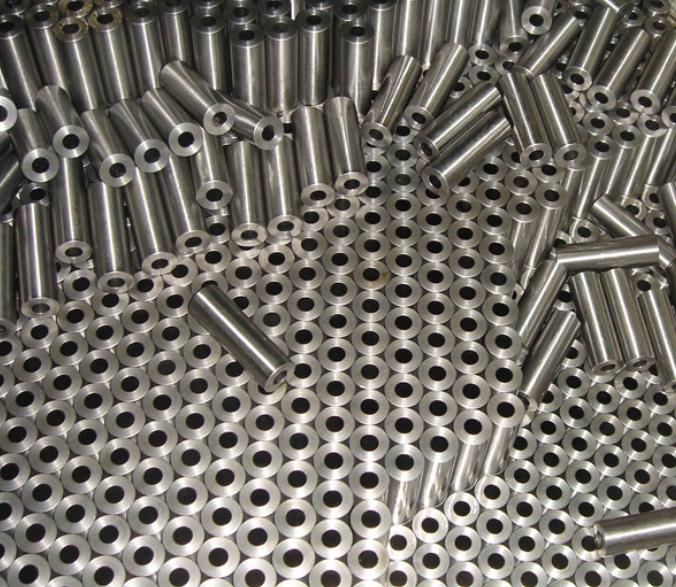

Cold rolled seamless steel pipe (DIN2391/EN10305) is a precision seamless steel pipe with high dimensional accuracy and good surface finish used in mechanical structures and hydraulic equipment. In addition to general steel pipes, low and medium pressure boiler steel pipes, high-pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, and other steel pipes, cold rolled (rolled) seamless pipes also include carbon thin-walled steel pipes, alloy thin-walled steel pipes, stainless thin-walled steel pipes, and special-shaped steel pipes. The diameter of cold-rolled seamless steel pipes can reach 6mm, the wall thickness can reach 0.25mm, and the outer diameter of thin-walled pipes can reach 5mm, with a wall thickness less than 0.25mm. Cold rolling has higher dimensional accuracy than hot rolling.

Hot rolled seamless pipes generally have an outer diameter greater than 32mm and a wall thickness of 2.5-75mm. They are divided into general steel pipes, low and medium pressure boiler steel pipes, high-pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, geological steel pipes, and other steel pipes.

The materials commonly used for seamless pipes mainly include: hot-rolled or cold-rolled alloy steel such as ASE1010, S20C, S35C, S45C SCM440 SCM420 SCM32, ST35 ST37 ST45 ST52 E235 E215 E355 4130 4140 4340, etc. Seamless pipes made of low-carbon steel such as S35 ST37 ST52 E235 E355 are mainly used for fluid transportation pipelines. Seamless pipes made of S45, 40Cr and other medium carbon steels are used to manufacture Machine element, such as stressed parts of automobiles and tractors. Seamless steel pipes are generally used to ensure strength and flattening tests. Hot rolled steel pipes are delivered in hot rolled or heat treated condition; Cold rolling is delivered in a heat treated state.

The main differences between hot-rolled and cold-rolled seamless pipes:

1. Cold rolled formed steel allows for local buckling of the cross-section, thereby fully utilizing the load-bearing capacity of the member after buckling; However, hot-rolled steel sections are not allowed to undergo local buckling.

2. The causes of residual stress generation in hot-rolled and cold-rolled steel sections are different, so there are also significant differences in the distribution of residual stress on the cross-section. The residual stress distribution on the cross-section of cold-formed thin-walled steel is curved, while the residual stress distribution on the cross-section of hot-rolled or welded steel is thin film.

3. The free torsional stiffness of hot-rolled section steel is higher than that of cold-rolled section steel, so the torsional resistance of hot-rolled section steel is better than that of cold-rolled section steel.

New Gapower Metal is professional manufacturer of hydraulic steel pipe.With an annual production of 10,000 tons of high precision seamless steel tube and 20,000 ton steel pipes and steel bar stock.

Post time: Jun-28-2023