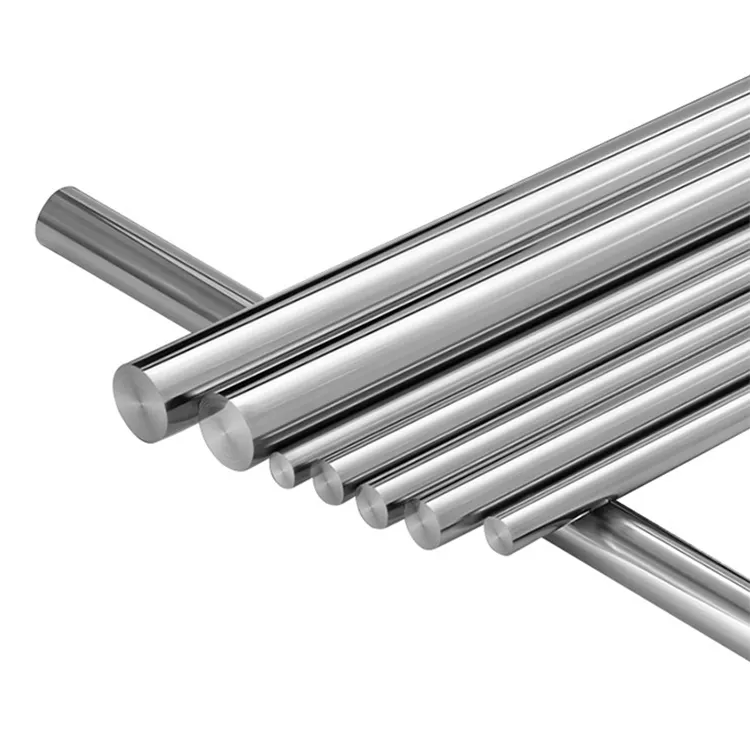

ASTM AISI 1212 1215 1140 1144 Free Cutting Steel bar

Product Detail

ASTM AISI 1212 1215 1140 1144 Free Cutting Steel bar are high sulfur medium-low carbon free-cutting steel, which has better cutting performance compared with 10# 25# 35# 45# steel, ASTM 1212 1215 1140 1144 can increase tool life by four times, increase productivity by 30%, and has higher strength and hardness.

Standard: ASTM A29/A29M-04

ASTM AISI 1212 1215 1140 1144 Free cutting steel are metal material that has good wear resistance and impact resistance. Free cutting steel is commonly used in the manufacturing of components, tools, or other equipment, such as machine tool blades, valve body clamps, etc. ASTM1212 1215 1140 1144 free cutting steel have excellent wear resistance, corrosion resistance, and oxidation resistance, so it can be widely used in various mechanical processing fields. ASTM1212 1215 1140 1144 free cutting steel exhibits excellent wear resistance at high temperatures, while at low temperatures it exhibits good compressive and extramural strength. In addition, the steel also has very high tensile strength and can withstand heavy loads. ASTM1212 1215 1140 1144 free cutting steel have excellent heat resistance and will not burn even when heated in flames.

Parameters

|

Size |

Round Bar | Dia 6-1200mm |

|

|

Plate/Flat/Block | Thickness: 6mm-500mm |

|

|

Width: 20mm-1000mm | |

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | |

| Type | Cold drawn/hot rolled | |

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | |

| Delivery condition | Forged; Hot rolled; Cold drawn | |

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | |

| Application | ASTM 1212 1215 1140 1144 are suitable for machining parts requiring high rigidity, such as lead screw, polished rod, rack and spline shaft, etc. | |

| Chemical Composition (%) | ||||

|

Grade |

C |

Mn |

P |

S |

|

1212 |

≤0.13 |

0.70-1.00 |

0.07-0.12 |

0.16-0.23 |

|

1215 |

≤0.09 |

0.75-1.05 |

0.04-0.09 |

0.24-0.33 |

|

1140 |

0.37-0.44 |

0.7-1.0 |

≤0.04 |

0.08-0.13 |

|

1144 |

0.40-0.48 |

1.35-1.65 |

≤0.04 |

0.24-0.33 |

| Equal different standards | ||||

|

AISI/ASTM |

GB |

EN10087 |

JIS |

DIN |

|

1212 |

Y12 |

- |

SUM21 |

- |

|

1215 |

Y15 |

11SMn30 |

- |

- |

|

1140 |

Y35 |

- |

SUM41 |

- |

|

1144 |

Y40Mn |

38SMn28 |

SUM43 |

44Mn28 |

Package&Shipping

By bundles, each bundle weight under 3 tons, for small outer

Diameter round bar, each bundle with 4 - 8 steel strips.

20 feet container contains dimension, length under 6000mm

40 feet container contains dimension, length under 12000mm

By bulk vessel, Freight charge is low by bulk cargo, and large

Heavy sizes can not be loaded into containers can shipping by bulk cargo

Quality Assurance

1.Strict according to Requirements

2.Sample: Sample is available.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers' request

4.Certificate: IATF16949, ISO9001, SGS etc.

5. EN 10204 3.1 Certification