DIN2445 ST37.4 ST44.4 ST52.4 Steel tube pipe

Product Detail

ST37.4 ST44.4 ST52.4 Steel Grade Seamless Steel Tube for dynamic Loads Normal Pressures 100 to 400 bar is our company mainly product. It is widely used in heavy duty truck, military industry, railway locomotive,engine filed and the gas line in special vehicle.They could meet the requirements because of high precision of Out diameter and Inner diameter. Also its anti corrosion performance.

Specification

| Standard | DIN2445 DIN1630 DIN2448 |

| Grade | ST37.4 ST4.4 ST52.4 |

| Delivery Condition | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) |

| Size | OD:4 to 219mm Thickness 0.5-20mm, Length: 3m,5.8,6 or according to requirements |

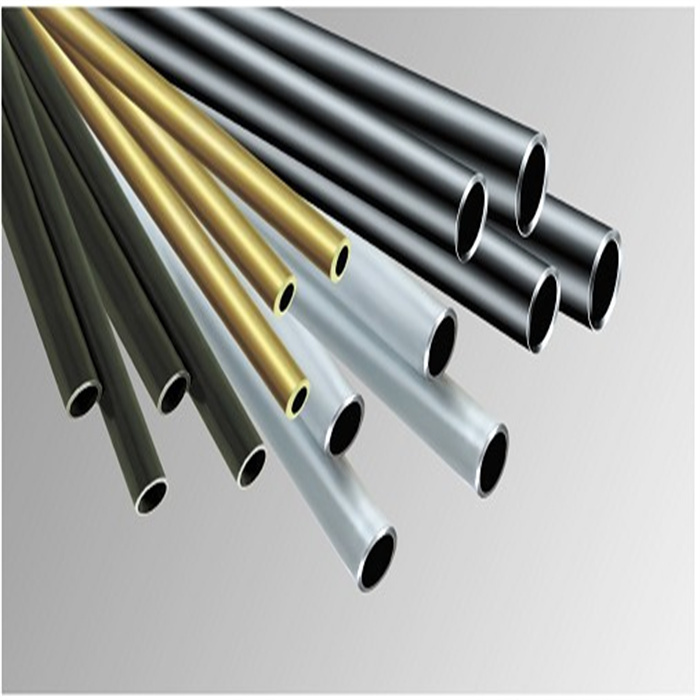

| Finish | 1.Bare Tube (No coating): Bright and smooth

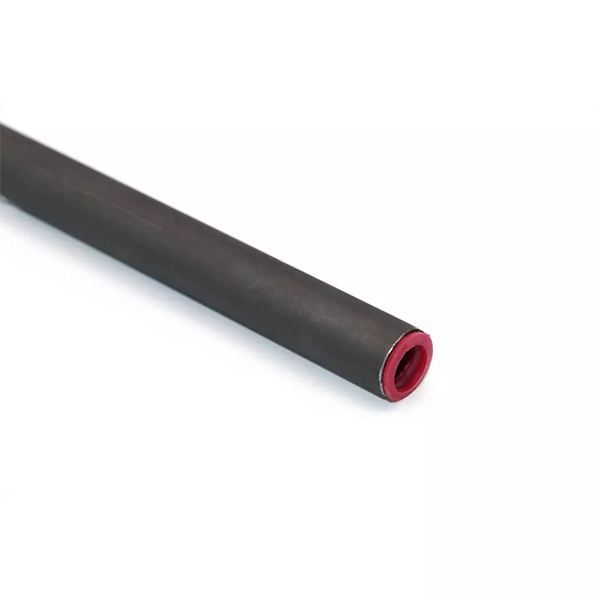

2.Galvanized surface (Sliver/Yellow/Colorful) Zinc coating of 8-12um 3.Black phosphate |

| Application | Hydraulic System; Car/bus; construction vehicle |

| Delivery time | A.3 days if this good is stock goods.

B. About 30 days according to the quantity |

|

COLD DRAWN SEAMLESS STEEL TUBE |

|||

|

Standards |

Steel Grades | Size Range | |

|

DIN |

2391 | ST35/45/52 | OD4 - 219mm × WT0.3 -20mm |

| 1629 | ST37/44/52 | OD4 - 219mm × WT0.3 -20mm | |

| 1630 | ST37.4/44.4/52.4 | OD4 - 219mm × WT0.3 -20mm | |

| 2445 | ST35/ST52/ST37.4//52.4 | OD4 - 219mm × WT0.3 -20mm | |

| 73000 | ST 35 / 45 / 52/ 37.4 / 44.4 /52.4 | OD3 - 30mm × ID 1 - 12.5 mm | |

|

GB/T |

8162 | 10/20/16Mn/35/45/30CrMo/ | OD4 - 219mm × WT0.3 -20mm |

| 8163 | 10/20/16Mn/35/45/30CrMo | OD4 - 219mm × WT0.3 -20mm | |

| 3639 | 10/20/16Mn/35/45/30CrMo | OD4 - 219mm × WT0.3 -20mm | |

| 3093 | 10/20/16Mn/35/45/30CrMo | OD3 - 30mm × ID 1 - 12.5 mm | |

|

EN |

10305-1 | E215/235/255/355 | OD4 - 219mm × WT0.3 -20mm |

| 10305-4 | E215/235/255/355 | OD4 - 219mm × WT0.3 -20mm | |

|

ASTM |

A822-A450 | A822 | OD4 - 219mm × WT0.3 -20mm |

| A179-A450 | A179 | OD4 - 219mm × WT0.3 -20mm | |

| A519 | 1010/1015/1025/1030/1045/

4130 /4140/etc |

OD4 - 219mm × WT0.3 -20mm | |

|

SAE |

J524 | Low carbon steel | OD4 - 219mm × WT0.3 -20mm |

| J529 | Low carbon steel | OD3 - 30mm × ID 1 - 12.5 mm | |

|

JIS |

G3445 | STKM11A/12A/12B/12C/13A/13B | OD4 - 219mm × WT0.3 -20mm |

| G3455 | STS35/38/42/49 | OD3 - 30mm × ID 1 - 12.5 mm | |

|

ISO |

8535 | ST 35 / 45 / 52/ 37.4 / 44.4 /52.4 | OD3 - 30mm × ID 1 - 12.5 mm |

|

NF |

A49-310 | TU37b/TU52b | OD4 - 219mm × WT0.3 -20mm |

|

BS |

3602 | CFS 360 | OD4 - 219mm × WT0.3 -20mm |

| 6323(-4) | CFS2/CFS3/CFS4/CFS5 | OD4 - 219mm × WT0.3 -20mm | |

|

ASTM |

A269 | 304,304L, 316, 316L | OD4 - 219mm × WT0.3 -20mm |

|

EN |

10216-5 | 1.4401, 1.4404 | OD4 - 219mm × WT0.3 -20mm |

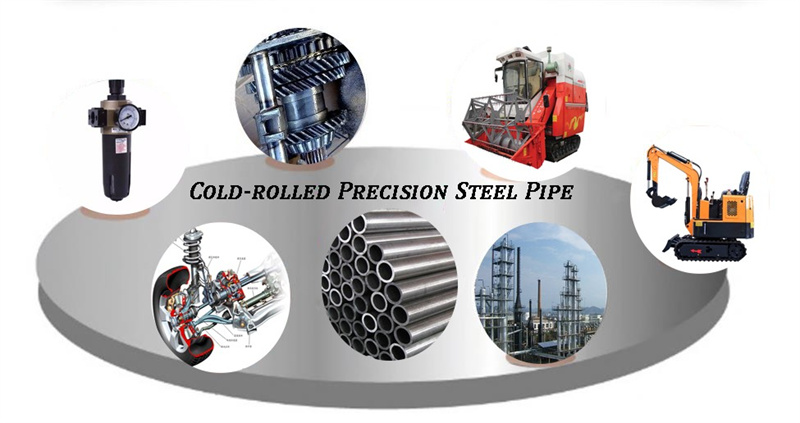

Application

1. Automotive fields

A. Fuel injection lines/nozzles

B. CNG (Compressed Nature Gas) tube-- Burst pressure: 1307Bar, Working Pressure: around 350bar

C. Drive transmission: Steering column elements

D. Gear shafts, hand brake, front axles, airbag inhalators, stabilizers, seat fasteners, front-wheel drive shafts

2. Hydraulic Fields

A. Hydraulic circuits (HPL), pneumatic lines, and hydraulic suspension

B. Hydraulic cylinders (HPZ)

Quality Assurance

1. Strict according to DIN2391/EN10305 or other standard.

2. Sample: Sample is free for test.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers' request

4.Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

Product packaging