EN/DIN High Precision Galvanized Seamless Steel Tube

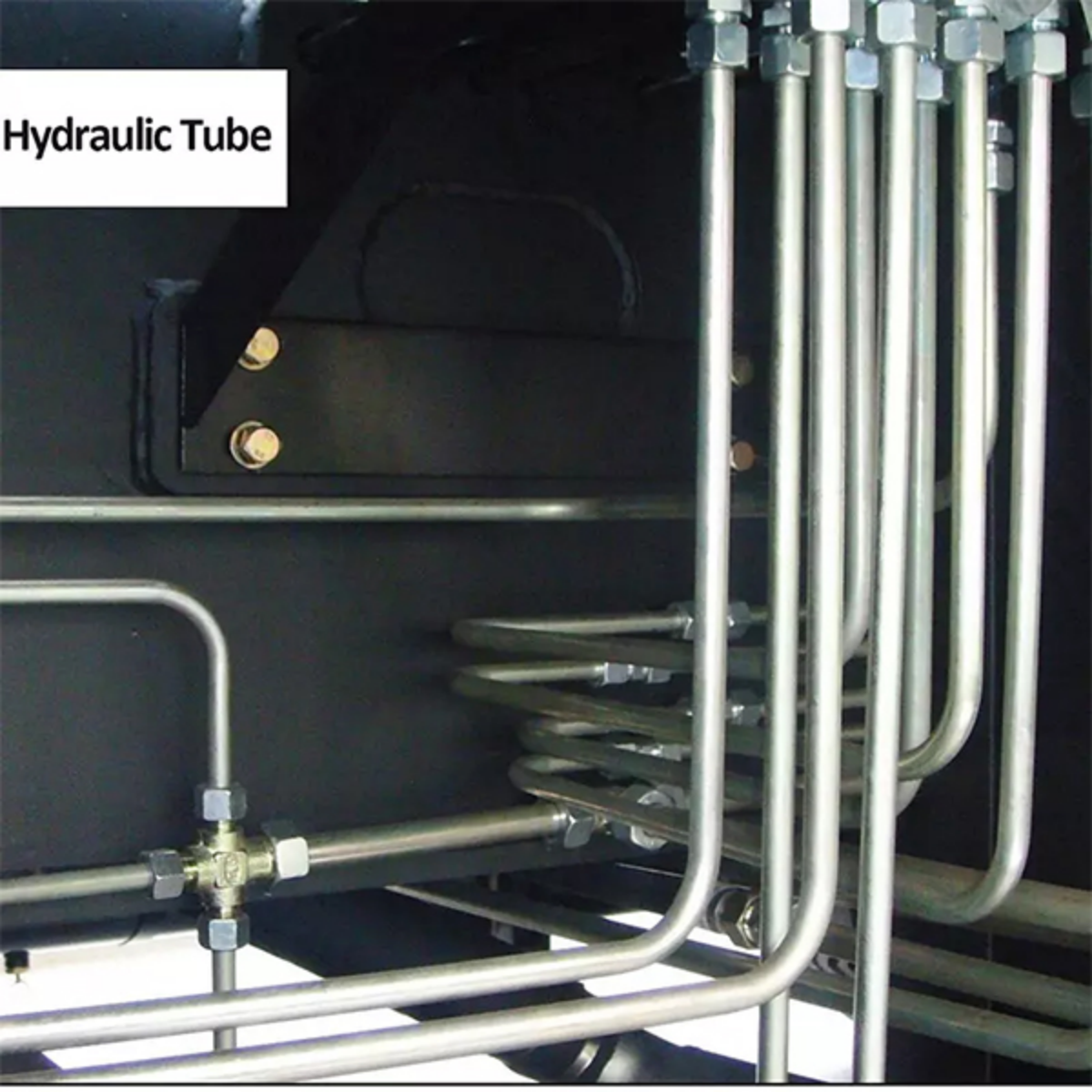

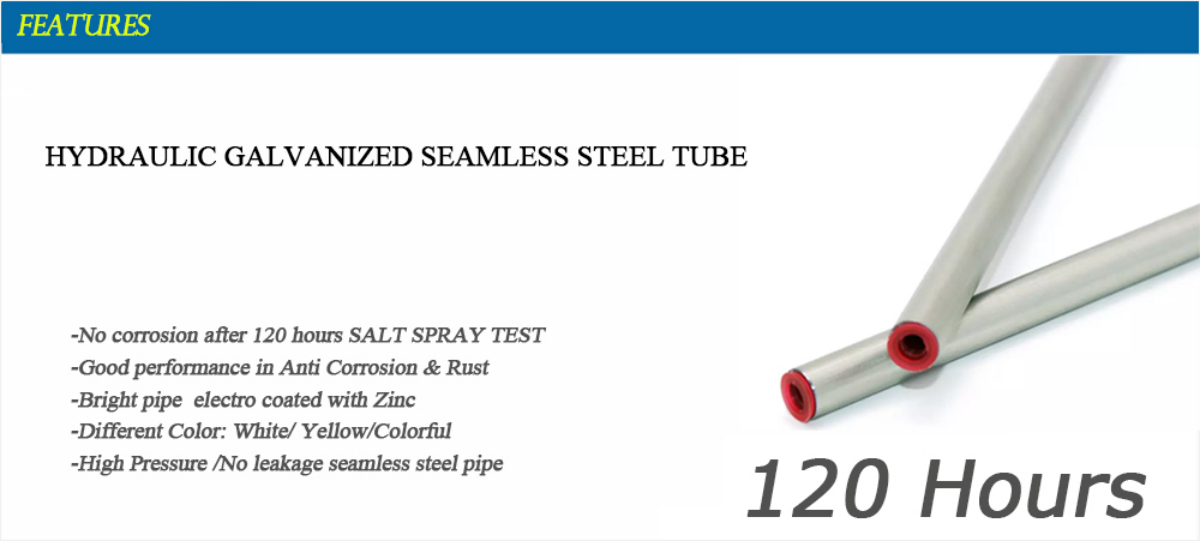

EN/DIN High Precision Galvanized Seamless Steel Tube is produced basing on DIN 2391-C and EN10305-4. It is widely used in hydraulic systems, machine tools, automobiles, ships, construction machinery and vehicles. The Hydraulic galvanized seamless steel tube with high precision has lots of advantages: No corrosion after 120 hours SALT SPRAY TEST; Good performance in Anti Corrosion & Rust; Bright pipe electric coated with Zinc; Different Color: White/ Yellow/Colorful; High Pressure /No leakage seamless steel pipe.

Specification

| Standard | DIN2391 DIN1630 EN10305 DIN2445 JIS G3445 SAE J524 |

| Grade | ST35/E235 ST37.4 ST45/E255 ST52/E355 |

| Delivery Condition | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) |

| Size | OD:4 to 219mm Thickness 0.5-35mm, Length: 3m,5.8,6 or according to requirements |

| Finish | Galvanized surface (Sliver/Yellow/Colorful) Zinc coating of 8-12um |

| Application | Hydraulic System; Car/bus; construction vehicle |

| Delivery time | A.3 days if this good is stock goods.B. About 30 days according to the quantity |

| HYDRAULIC PRECSION STEEL TUBE IN STOCK | ||||||||||

| OD | Thickness(mm) | |||||||||

| mm | ||||||||||

| 4 | 4*1 | |||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | |||||||

| 8 | 8*1 | 8*1.5 | 8*2 | |||||||

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 | ||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 | |||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | |||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 | ||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 | ||

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 | ||

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 | |

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 | |

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 | |

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 | |

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 | 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 | |

| 34 | 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |

| 35 | 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | ||

| 40 | 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||

| 42 | 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||

| 45 | 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||

| 46 | 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||

| 48 | 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||

| 50 | 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||

| 54 | 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||

| 60 | 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | |||

| 65 | 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 | ||||

| 75 | 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 | |||||

| 76 | 76*4 | 76*4.5 | 76*5 | 76*6 | ||||||

| 89 | 89*6 | |||||||||

| Note: We could produce other sizes as your requirements. Surface Treatment: Bright, Galvanized, Phosphating etc. | ||||||||||

Chemical composition

|

Steel Grade |

C |

Si |

Mn |

P |

S |

Al |

|

|

Name |

No. |

max |

max |

max |

max |

max |

max |

|

E215 |

1.0212 |

0.1 |

0.05 |

0.7 |

0.025 |

0.015 |

0.025 |

|

E235 |

1.0308 |

0.17 |

0.35 |

1.2 |

0.025 |

0.015 |

— |

|

E355 |

1.058 |

0.22 |

0.55 |

1.6 |

0.025 |

0.015 |

— |

|

ST35 |

1.0308 |

0.17 |

0.35 |

0.4(min) |

0.025 |

0.025 |

— |

|

ST45 |

1.0408 |

0.21 |

0.35 |

0.4(min) |

0.025 |

0.025 |

— |

|

ST52 |

1.058 |

0.22 |

0.55 |

1.6 |

0.025 |

0.025 |

— |

Mechanical properties

| Steel Grade | Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation(%) | |

| Name | No. | ReH (min) | Rm(min) | A(min) |

| E215 | 1.0212 | 215 | 290 to 430 | 30 |

| E235 | 1.0308 | 235 | 340 to 480 | 25 |

| E355 | 1.058 | 355 | 490 to 630 | 22 |

| ST35 | 1.0308 | 235 | 340 to 480 | 25 |

| ST45 | 1.0408 | 255 | 440 to 570 | 21 |

| ST52 | 1.058 | 355 | 490 to 630 | 22 |

Tolerance

|

OD |

Allowable tolerance |

Special Tolerance |

||

|

GB/T3639 |

DIN2391 |

OD |

WT |

|

|

4mm-20mm |

±0.10mm |

±0.08mm |

±0.05mm |

±0.05mm |

|

20mm-30mm |

±0.10mm |

±0.08mm |

±0.08mm |

±0.08mm |

|

31mm-40mm |

±0.15mm |

±0.15mm |

±0.10mm |

±0.08mm |

|

41mm-60mm |

±0.20mm |

±0.20mm |

±0.15mm |

±0.15mm |

|

61mm-80mm |

±0.30mm |

±0.30mm |

±0.20mm |

±0.20mm |

|

81mm-120mm |

±0.45mm |

±0.45mm |

±0.30mm |

±0.30mm |

Delivery condition

| Designation | Symbol | Description |

| Cold finished (hard) | BK(+C) | Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation |

| Cold finished (Soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding) |

| (+LC) | ||

| Cold finished and stress-relieved | BKS(+SR) | Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK(+A) | The last Cold forming process is followed by annealing in a controlled atmosphere. |

| Normalized | NBK(+N) | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Quality assurance

1.Strict according to DIN2391/EN10305 or other standards.

2. Sample: Sample is free for test.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers' request

4.Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

Application