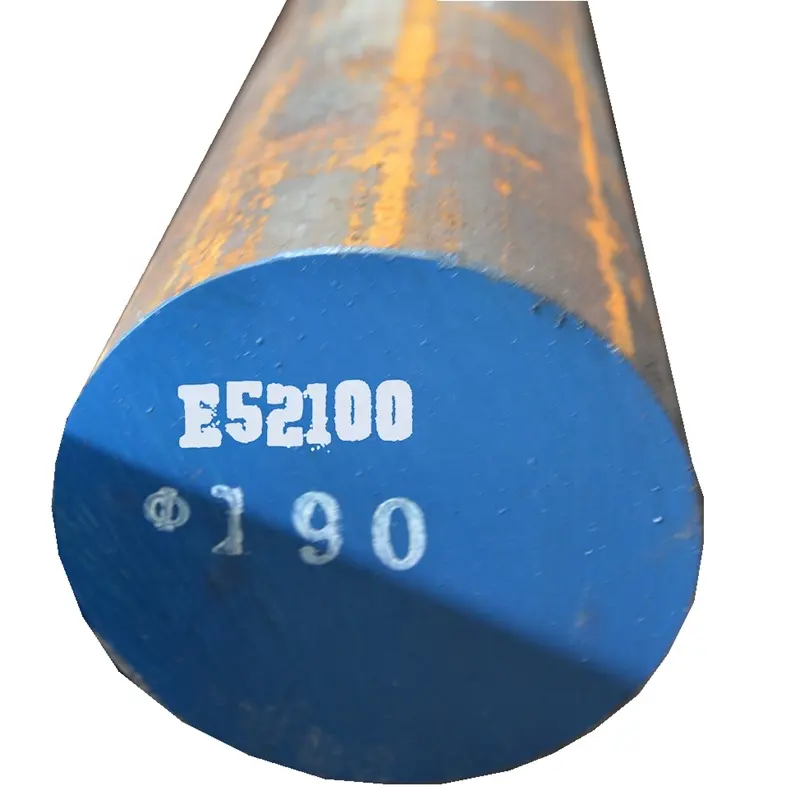

AISI SAE 4130 4140 4145H Steel Round Bar Hollow Rod

Features

4130 4135 4140 4145H steel bars are a low carbon alloy steel. They are belong to Chrome-Molly alloy that contains chromium and molybdenum as strengthening agents.

4130 round steel bar has good work ability, minimal processing deformation, and excellent fatigue resistance. It belongs to the category of medium to high harden ability steel. After heat treatment, 4140 has good strength and comprehensive mechanical properties, good process ability, and high yield. The service temperature is 427 degrees Celsius.

4140 has high strength, harden ability, toughness, and deformation during quenching. It has high creep strength and endurance strength at high temperatures. Used for manufacturing forgings that require higher strength and larger quenched and tempered sections than 4135 steel, such as large gears for locomotive traction, booster transmission gears, rear axles, connecting rods and spring clips that are heavily loaded.

Specification

| Product Name | AISI ASTM 4130 4135 4140 Alloy Steel Bar | |

| Material | ASTM | 4130,4135 4140,4145H |

| DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Standard | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm to 600mm | |

| Surface | Black painted, Bare, Polished, Chrome Plated | |

| Specifications | Round bar | 8mm~800mm |

| Angle bar | 3mm*20mm*20mm~12mm*800mm*800mm | |

| Square bar | 4mm*4mm~100mm*100mm | |

| Flat bar | 2*10mm~100*500mm | |

| Hexagonal | 4mm~800mm | |

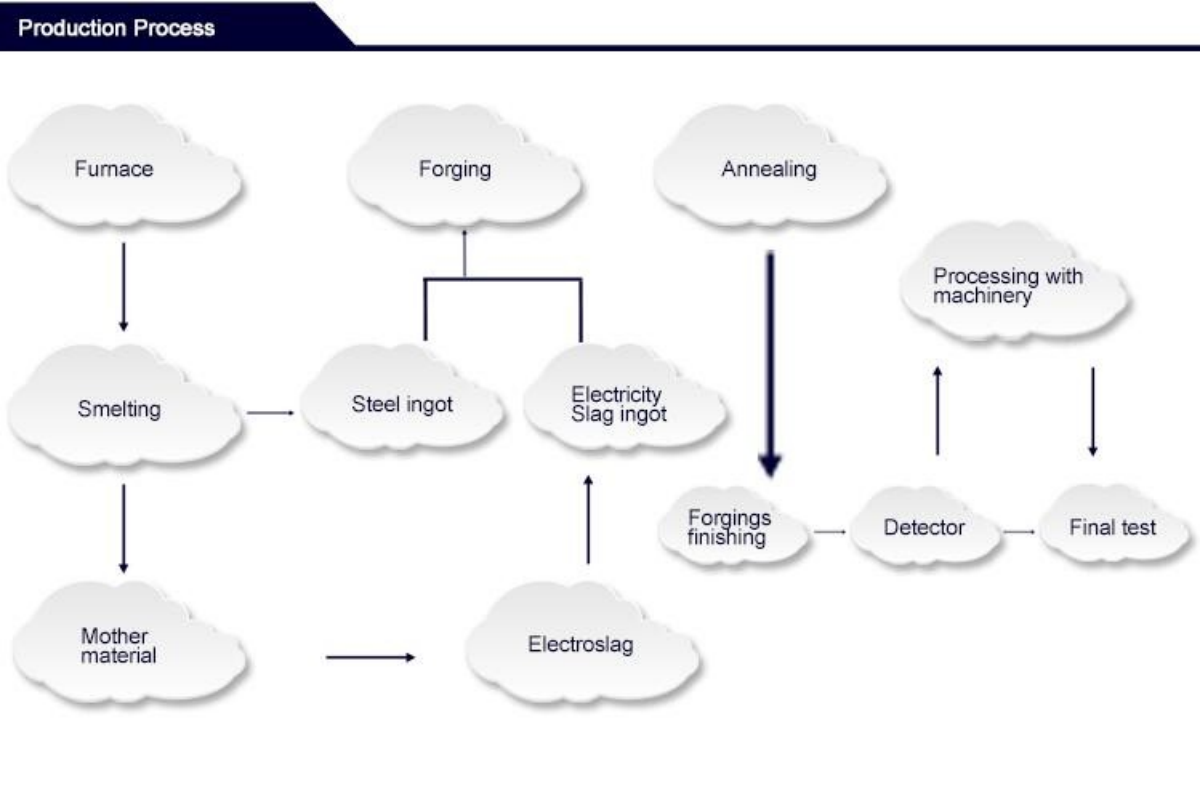

| Process | Electric furnace melted, forged and annealed, round bar turned. | |

| Hardness: | HBS 217Max (Different from heat treatment) | |

| UT Test | SEP 1921/84/2 C/c class. | |

| Tolerance | Dia -0/+ 0~5mm, Thickness -0/+ 0~5mm, Width: -0/+ 0~10mm. | |

| Length | 2m,4m,5.8m,6m,11.8m,12m or as required. | |

| Package | Seaworthy Packing. | |

| Equal dIfferent standard | |||

| AISI | GB | DIN | JIS |

| 4130 | 30CrMo | 1.7218 | SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | SCM440 |

| 4135 | 35Crmo | 1.7220(34CrMo4) | SCM432 |

| 4145H | — | — | — |

Chemical Composition

| Chemical Composition (%) | |||||||

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Mechanical Properties

| Characteristics: |

| 1.Low alloy steel containing molybdenum and chromium as strengthening agents; |

| 2.Excellent from the fusion weldability standpoint; |

| 3.The alloy can be hardened by heat treatment. |

Tolerance

| Delivery Condition |

| 1.Hot rolled |

| 2.Annealed |

| 3.Normalized |

| 4. Quench and Tempered |

Conditions of heat treatment

1.Annealing: 880℃ Furnace cooling

2.Normalization: 880~870℃ Air cooling

3.Hardening: 820~870℃ Water cooling

4.Tempering: 550~650℃ Rapid cooling

Mechanical Properties can be gotten by different heat treatment.

Package

1.By bundles, each bundle weight under 3 tons, for small outer

diameter round bar, each bundle with 4 - 8 steel strips.

2.20 feet container contains dimension, length under 6000mm

3.40 feet container contains dimension, length under 12000mm

4.By bulk vessel, Freight charge is low by bulk cargo, and large

heavy sizes can not be loaded into containers can shipping by bulk cargo

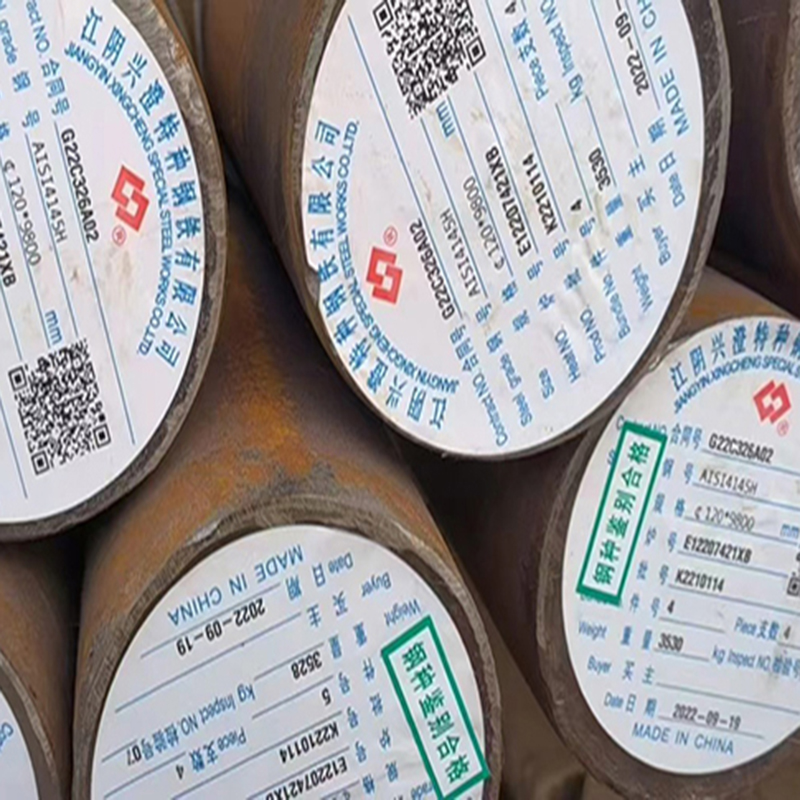

Quality assurance

1.Strict according to Requirements

2. Sample: Sample is available.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers' request

4.Certificate: IATF16949, ISO9001, SGS etc.

5. EN 10204 3.1 Certification