DIN 34crnimo6 steel round bar 1.6582 steel bar

Features

34CrNiMo6 Steel is an important alloy engineering steel grade as per BS EN 10083-3:2006. 34CrNiMo6 steel has high strength, high toughness and good harden-ability.

34CrNiMo6 is applied in industries such as aviation, automotive, automotive, and national defense. 34CrNiMo6 can undergo heat treatment such as normalizing, tempering, and quenching. It is used to manufacture chains, screws, gears, arms, rollers, and various other mechanical parts.

Specification

| Size | Round | Dia 6-1200mm |

| Plate/Flat/Block | Thickness | |

| 6mm-500mm | ||

| Width | ||

| 20mm-1000mm | ||

| Process | EAF+LF+VD+Forged+Heat treatment(optional) | |

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | |

| Surface condition | Black; Peeled; Polished; Machined; Grind; Turned; Milled | |

| Delivery condition | Forged; Hot rolled; Cold drawn | |

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | |

| Delivery time | 30-45 days | |

| Application | 34CrNiMo6 are used for heavy machinery axle,turbine shaft blade, high load of transmission parts, fasteners, crank shafts, gears, as well as heavily loaded parts for motor construction etc. | |

Chemical composition(%)

| Carbon C | 0.3~0.38 |

| Silicon Si | 0.4 |

| Manganese Mn | 0.5~0.8 |

| Sulfur S | ≤ 0.035 |

| Phosphorus P | ≤ 0.025 |

| Chromium Cr | 1.3~1.7 |

| Nickel Ni | 1.3~1.7 |

| Molybdenum Mo | 0.15-0.3 |

Mechanical Properties

| Tensile strength σ b (MPa) | 850~1400 |

| Yield strength σ s (MPa) | ≥690~1000 |

| Elongation δ (%) | ≥9~15% |

| Hardness | 239~259 HB |

| Equal dIfferent standard | |

|

Grade |

Standard |

|

34CrNiMo6 (1.6582) |

EN 10083-3 |

|

4337 |

ASTM A29 |

Delivery condition

Hot forged bar, usually the delivery condition is hot forged, annealed/QT rough turned/Black surface.

Hot rolled bar, usually the delivery condition is hot rolled, annealed/QT, Black surface.

Tolerance

| Diameter(mm) | Tolerance | ||

| Forged Steel Round Bar | 80-600 | Black Surface:0~+5 | Rough Machined or Turned:0~+3 |

| 650-1200 | Black Surface:0~+15 | Rough Machined or Turned:0~+3 | |

| Hot Rolled Steel Round Bar | 16-310 | Black Surface:0~+1 | Peeled:H11 |

| Cold Drawn Steel Round Bar | 6-100 | Black Surface:H11 | Peeled:H11 |

Package

1.By bundles, each bundle weight under 3 tons, for small outer

diameter round bar, each bundle with 4 - 8 steel strips.

2.20 feet container contains dimension, length under 6000mm

3.40 feet container contains dimension, length under 12000mm

4.By bulk vessel, Freight charge is low by bulk cargo, and large

heavy sizes can not be loaded into containers can shipping by bulk cargo

Certificate of Quality:Issued in English, in addition the normal terms, production process, the mechanical property (yield strength, tensile strength, elongation and hardness), forged ratio, UT test result, Grain size, heat treatment methods and the sample of is shown on the Certificate of Quality.

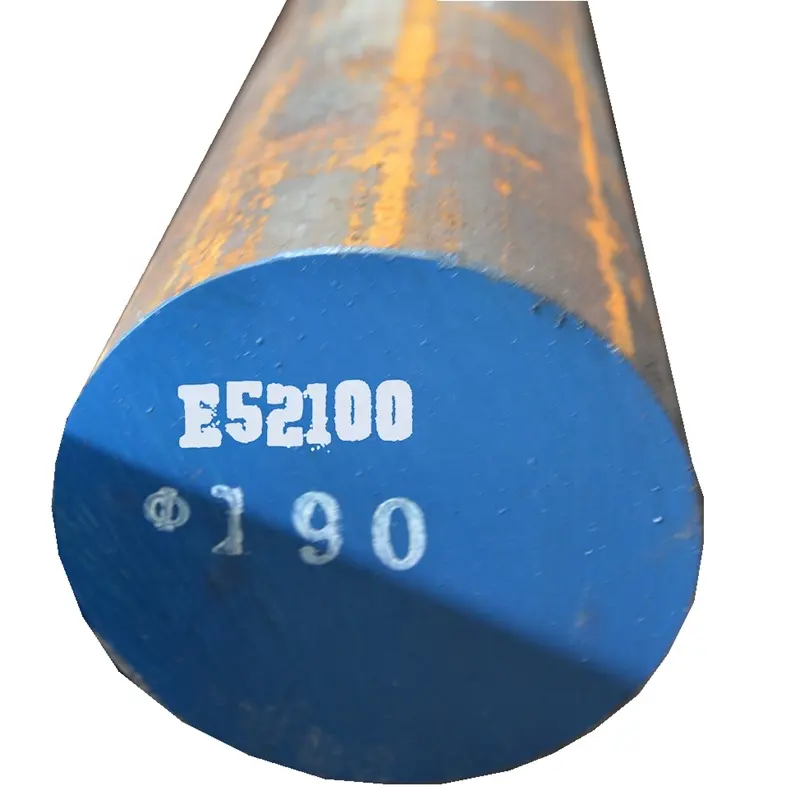

Marking: Heat No. will be cold stamped and Steel grade, diameter (mm), length (mm), and the manufacturer LOGO and weight (kg) is painted

Quality assurance

1. Strict according to Requirements

2. Sample: Sample is available.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers' request

4. Certificate: IATF16949, ISO9001, SGS etc.

5. EN 10204 3.1 Certification