DIN1629 ST37 ST44 ST52 Steel Pipe

Specification

DIN1629 is a technical standard for the production, manufacturing, and delivery of German standard seamless steel pipes. The standard specifies the type of seamless steel pipe, manufacturing method, chemical composition and mechanical properties of steel grade, process performance, Surface states, dimensional tolerance and air tightness inspection. The inspection method, process, inspection documents, and marking requirements for the finished product were explained.

DIN1629 Special requirements seamless annular non alloy steel pipes include ST37, ST44, and ST52 steel grade. According to the standard, the products are mainly divided into hot rolled and cold drawn. DIN1629 seamless steel pipe is mainly used in chemical equipment and transmission

Specification

| Standard | DIN 1629 |

| Grade | ST37 ST44 ST52 |

| Delivery Condition | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) AS Rolled |

| Size | OD:4 to 610mm

Thickness: 0.5-20mm, Length: 3m,5.8,6 or according to requirements |

| Finish | 1.Bare Tube (No coating): Bright and smooth

2.Galvanized surface (Sliver/Yellow/Colorful) Zinc coating of 8-12um 3.Black phosphate |

| Application | Hydraulic System; Car/bus; construction vehicle/ Mechanical |

| Delivery time | A.3 days if this good is stock goods.

B. About 30 days according to the quantity |

Different Standards Pipe Could be customized

|

SEAMLESS STEEL TUBE |

|||

|

Standards |

Steel Grades | Size Range | |

|

DIN |

2391 | ST35/45/52 | OD4 - 219mm × WT0.3 -20mm |

| 1629 | ST37/44/52 | OD4 - 219mm × WT0.3 -20mm | |

| 1630 | ST37.4/44.4/52.4 | OD4 - 219mm × WT0.3 -20mm | |

| 2445 | ST35/ST52/ST37.4//52.4 | OD4 - 219mm × WT0.3 -20mm | |

| 73000 | ST 35 / 45 / 52/ 37.4 / 44.4 /52.4 | OD3 - 30mm × ID 1 - 12.5 mm | |

|

GB/T |

8162 | 10/20/16Mn/35/45/30CrMo/ | OD4 - 219mm × WT0.3 -20mm |

| 8163 | 10/20/16Mn/35/45/30CrMo | OD4 - 219mm × WT0.3 -20mm | |

| 3639 | 10/20/16Mn/35/45/30CrMo | OD4 - 219mm × WT0.3 -20mm | |

| 3093 | 10/20/16Mn/35/45/30CrMo | OD3 - 30mm × ID 1 - 12.5 mm | |

|

EN |

10305-1 | E215/235/255/355 | OD4 - 219mm × WT0.3 -20mm |

| 10305-4 | E215/235/255/355 | OD4 - 219mm × WT0.3 -20mm | |

|

ASTM |

A822-A450 | A822 | OD4 - 219mm × WT0.3 -20mm |

| A179-A450 | A179 | OD4 - 219mm × WT0.3 -20mm | |

| A519 | 1010/1015/1025/1030/1045/

4130 /4140/etc |

OD4 - 219mm × WT0.3 -20mm | |

|

SAE |

J524 | Low carbon steel | OD4 - 219mm × WT0.3 -20mm |

| J529 | Low carbon steel | OD3 - 30mm × ID 1 - 12.5 mm | |

|

JIS |

G3445 | STKM11A/12A/12B/12C/13A/13B | OD4 - 219mm × WT0.3 -20mm |

| G3455 | STS35/38/42/49 | OD3 - 30mm × ID 1 - 12.5 mm | |

|

ISO |

8535 | ST 35 / 45 / 52/ 37.4 / 44.4 /52.4 | OD3 - 30mm × ID 1 - 12.5 mm |

|

NF |

A49-310 | TU37b/TU52b | OD4 - 219mm × WT0.3 -20mm |

|

BS |

3602 | CFS 360 | OD4 - 219mm × WT0.3 -20mm |

| 6323(-4) | CFS2/CFS3/CFS4/CFS5 | OD4 - 219mm × WT0.3 -20mm | |

|

ASTM |

A269 | 304,304L, 316, 316L | OD4 - 219mm × WT0.3 -20mm |

|

EN |

10216-5 | 1.4401, 1.4404 | OD4 - 219mm × WT0.3 -20mm |

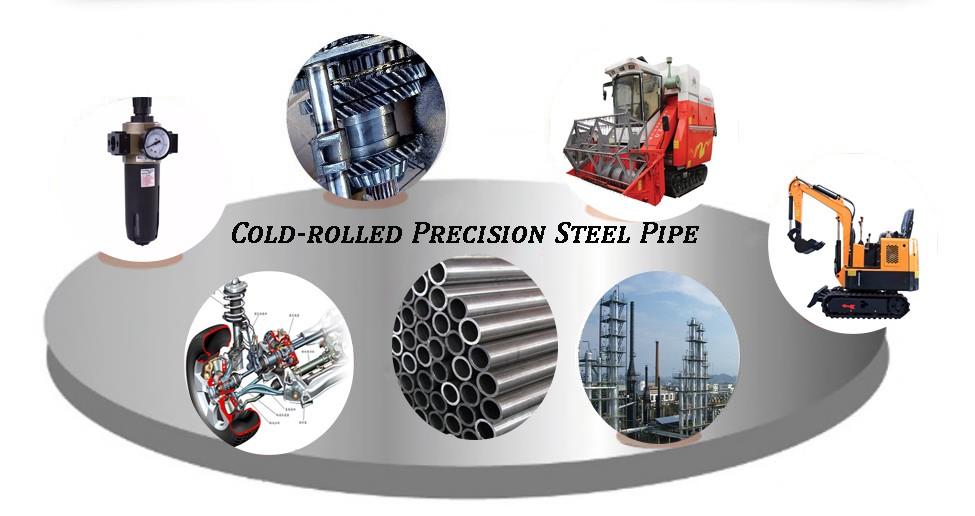

Application

Automotive fields

A. Fuel injection lines/nozzles

B. CNG (Compressed Nature Gas) tube-- Burst pressure: 1307Bar, Working Pressure: around 350bar

C. Drive transmission: Steering column elements

D. Gear shafts, hand brake, front axles, airbag inhalators, stabilizers, seat fasteners, front-wheel drive shafts

2. Hydraulic Fields

A. Hydraulic circuits (HPL), pneumatic lines, and hydraulic suspension

B. Hydraulic cylinders (HPZ)

Quality assurance

1. Strict according to DIN2391/EN10305 or other standard.

2. Sample: Sample is free for test.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers' request

4.Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

1-Strengthen the inspection of products in each production stage

2-Equipped with complete testing equipment: non-destructive eddy current testing, high pressure resistance testing machine, universal mechanical tensile testing machine, bending flattening flares testing machine, cleanliness analyzer, metal element analyzer.

3-Meet the mechanical properties of products, process performance test, provide a powerful guarantee for qualified products .