Steel Tie Bar for Injection Molding Machine

Features

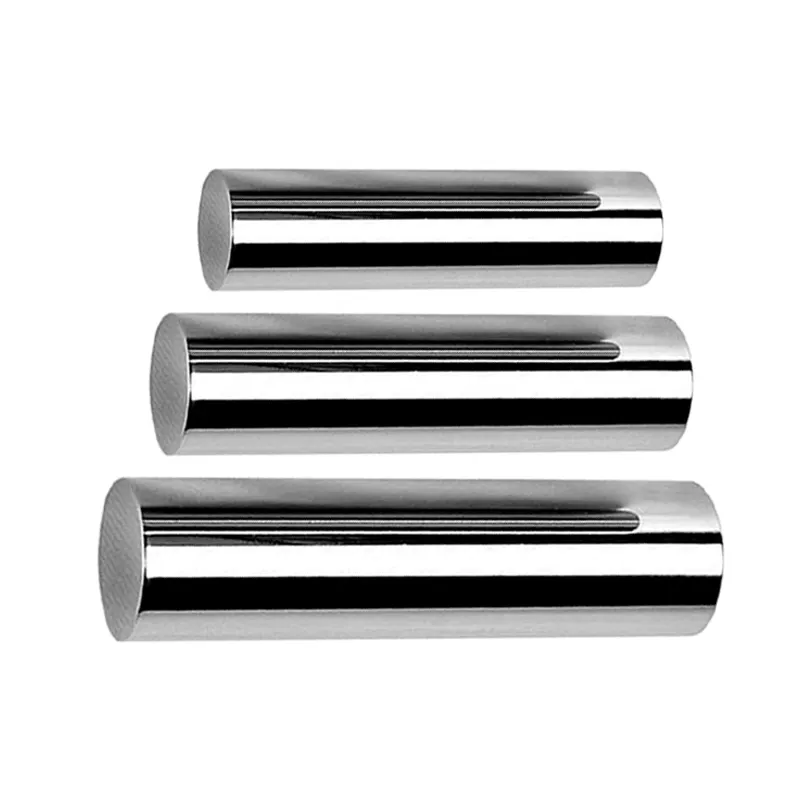

Injection Machine Tie Bar

Injection Molding machine tie bar is a guideline for mold platen movement, it's normally made by 4140 material with hard chromed on surface, though also may use with SAE1045 S45C, CK45 40Cr, 38CrMoAla material. The surface roughness and strength can offer low noise and precise clamping of injection

Specification

New Gapower Metal supply the good quality with proper tolerances and matching specifications.

-Material: High quality 38CrMoAlA ,SAE4140 S45C CK45,40Cr

-Treatment: Nitriding, Electroplating

-Diameter : Can be customized

-Application: for injection machine

-Advantages: ensure consistent and quality molding.Improved product quality

Specification

| Product | Material Base | Treatment | Technical Parameter | Application |

| Tie bar | 38CrMoAlA | Nitriding | Tempering hardness:HB260-280 Nitriding hardness:HV950 Nitride layer depth:0.4-0.6mm |

For injection machine |

| 4140 | Chromed Plated | Tempering hardness:HB250-280 Electroplating thickness:0.02-0.03mm |

||

| SAE 1045 | Chromed Plated | Tempering hardness:HB210-260 Electroplating thickness:0.02-0.03mm |

||

| CK45 | Chromed Plated | Tempering hardness:HB210-260 Electroplating thickness:0.02-0.03mm |

||

| S45C | Chromed Plated | Tempering hardness:HB210-260 Electroplating thickness:0.02-0.03mm |

Tie bar application

For good plasticizing effect,we have different designs of screw and barrel for extruder or injection to meet customer's demand.Our factory manufactures with high-quality material, applying the method of hardening and tempering and nitriding, thus it enjoys the characteristics of long working life, wear resistance, and anti corrosion. Besides, the technique of hard alloy spraying or chrome plating can be used on the working surface of screw, which will make it have better using effectiveness.

Our Advantages

1. Screw and barrel for various models

2. Professional engineers design for you

3. Thousands of drawings can supply for you

4. Insist on developing screw and barrel for more injection and extruder machine models

5. Main market: Southeast Asia,Eastern Europe, Africa

Quality assurance

1. Strict according to Requirements

2. Sample: Sample is available.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers' request

4. Certificate: IATF16949, ISO9001, SGS etc.

5. EN 10204 3.1 Certification

FAQ

Q1: Do you accept small order?

A: If your order bearings are our standard size, we accept even 1pcs.

Q2: Can I get free sample?

A: Yes. Limited,free sample available, freight cost must be paid by your side.

Q3: Are you factory or trade company?

A: We are manufacturer, New Gaopwer Metal factory.

Q4: Can we mark our brand on your bearings and packing?

A: Yes, we support OEM your brand, the details let’s negotiation.

Q5: How long is the delivery?

A: Small orders usually takes 3-7 days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

Payment

TT, Western Union, Paypal, L/C.

Transport:

1: DHL, FEDEX,TNT, UPS, EMS

2: By sea, By air.