1045 CK45 S45C GCr15 4140 Chrome Plated Hard Shafts

Features

Chrome Plated Hard Shafts are manufactured using precision cold drawing bar or hot rolled bar, precision grinding, hard chrome plating and high-precision polishing processes , and all indicators meet the standard. It provides precision piston rods, guide shafts, guide pillars, guide rods, and finished shaft products for hydraulic pneumatic, textile, printing, light industry packaging, plastic machinery and other mechanical industries. Our main products include piston rods, hollow shafts, optical shafts, grinding rods, high-frequency quenching shafts, screw shafts, etc.

The optical axis is divided into hard axis and soft axis. Chrome plated hard shafts are belong to hard axis.

In precision optical shafts, there are usually requirements for surface hardness. The purpose of external surface hardness is to improve wear resistance. For metal materials, the harder the hardness, the more wear-resistant it is. However, the harder the core, the lower the toughness, and the lower the load-bearing and impact resistance. Therefore, for important shaft requirements: external hardness and internal toughness.

Chemical composition

| Size | φ6-330mm |

| Length | 0.5-10.5m |

| Material | SAE1045 S45C CK45 Gcr15 4140 40Cr 27SiMn |

| Tolerance | ISO f7 g6 h6 h9 etc(or as requirement) |

| Chrome Thickness | 15-30μmm |

| Hardness | HRC 58-64 |

| Roughness | Ra 0.2μm(max) |

| Straightness | 0.2/1000 mm |

| Yield Strength | >320Mpa (As steel grade ) |

| Tensile Strength | >580Mpa (As steel grade ) |

| Elongation | >15% (As steel grade ) |

| Condition | 1.Hard chrome plated

2.Induction Hardened 3.Quenched& Tempered 4.Induction hardened with Q&T |

| Application | Hydraulic shafting, pneumatic piston rods, pump shafting, precision piston rods, guide rods etc |

Mechanical properties

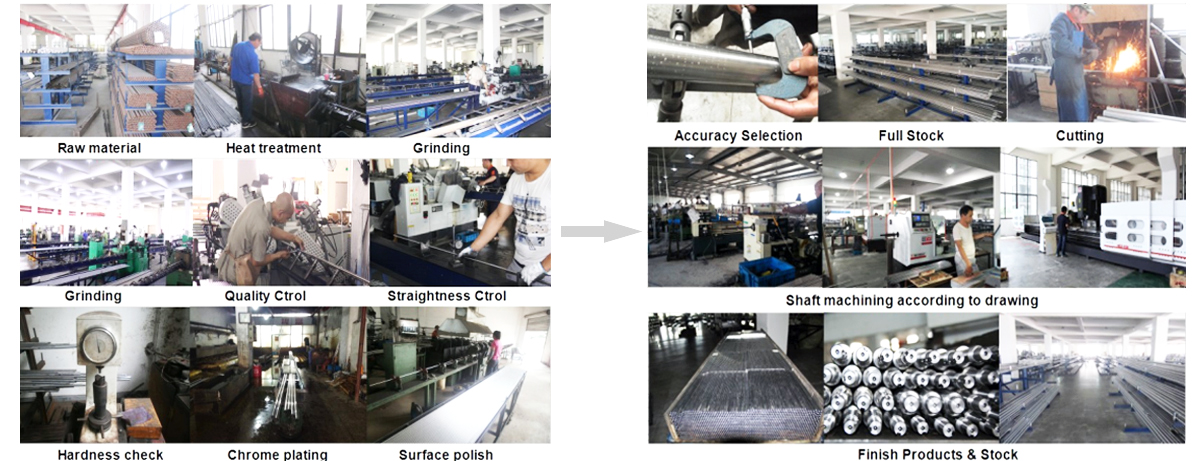

Chrome Plated Shafts produce process includes:

Choose raw material(steel bar)→heat treatment(QT)→grinding→quality control(tolerance test)→straight→hardness test→chrome plated→surface polish→accuracy section→full stock→cutting→shaft machining according to drawn→finish products→delivery.

Product application

Chrome Plated Hard Shafts are widely used in CNC machines, medical and food machinery, fitness machinery, packaging machinery, printing machinery, and other machinery supporting equipment.

Quality assurance

1. Strict according to standard and requirements

2. Sample: Sample is free for test.

3. Tests: Tensile test / Eddy current / Chemical composition test according to customers' request

4.Certificate: IATF16949, ISO9001, SGS etc.

5. EN 10204 3.1 Certification

FAQ

Q1: Do you accept small order?

A: If your order bearings are our standard size, we accept even 1pcs.

Q2: Can I get free sample?

A: Yes. Limited,free sample available, freight cost must be paid by your side.

Q3: Are you factory or trade company?

A: We are manufacturer, New Gaopwer Metal factory.

Q4: Can we mark our brand on your bearings and packing?

A: Yes, we support OEM your brand, the details let’s negotiation.

Q5: How long is the delivery?

A: Small orders usually takes 3-7 days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

Payment

TT, Western Union, Paypal, L/C.

Transport:

1: DHL, FEDEX,TNT, UPS, EMS

2: By sea, By air.