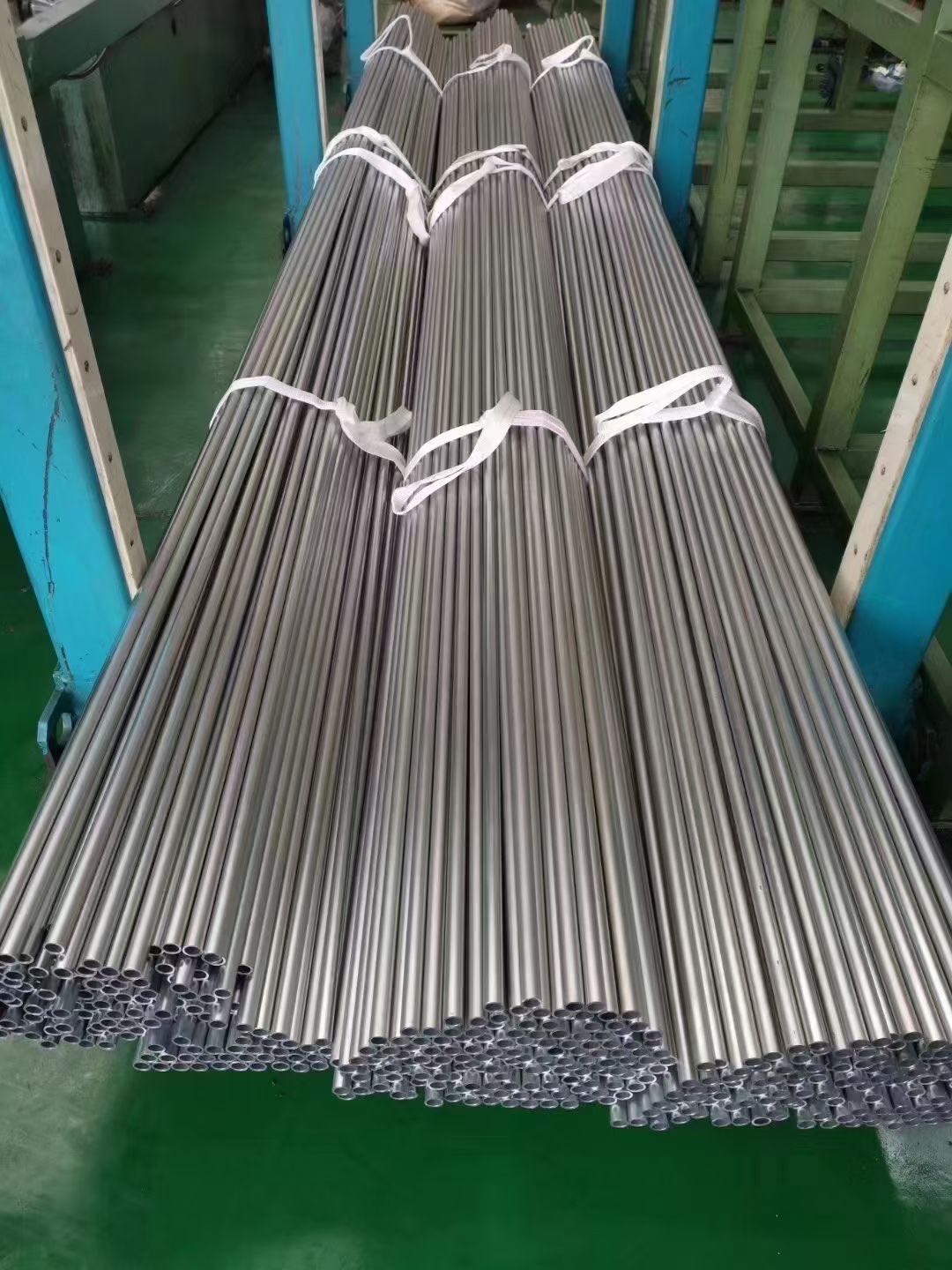

STKM11A STKM14B steel tube for car

Specification

STKM11A is a steel grade for carbon steel pipes used in mechanical structures, sourced from standard JIS G3445, and is a Japanese grade. STKM11A steel pipe grade, material equivalent to SPHC, σ B ≥ 290MPa; Carbon steel for STKM mechanical structures;

The SPHC brand was originally a German brand and was also used in Japan. Later, it was introduced by the domestic steel mill Baosteel, representing hot-rolled steel plates (which correspond to SPCC), equivalent to the hot-rolled plates of 10 # and 15 # steel in the national standard GB699 (National Standard for High Quality Carbon Structural Steel), with a carbon content range of around 0.1% -0.15%

Surface Treatment:

1.Bared

2.Black Painted (varnish coating)

3.Galvanized

4.Oiled

5.According to customers.

JIS STKM11A~18C/DIN ST52/ASTM A106, the precision and surface roughness of cold drawn precision steel pipes with inner and outer diameters are superior to hot-rolled pipes. The specifications can be customized to meet higher requirements for tensile strength, yield strength, elongation, etc; Cold drawn precision steel pipes with inner and outer diameters can be used for pneumatic cylinders; Oil pressure cylinder; Motorcycle and bicycle shock absorbable; Air conditioner condenser; Locomotive front fork and rear fork; Mechanical arm; Film recycling granular; Exhaust pipe; Bottle blowing machine; Leveling machine; Jack; Cultivator; Roller for printing machinery, etc.

JIS G3445 Precision steel tubes are mainly used in automobile and precision machinery parts for cars and cylinder. pressure use, and also for transporting steam, water, gas pipe lines.

Chemical Composition

|

Grade |

Designation |

Unit (%) |

||||||

|

C |

Si |

Mn |

P |

S |

Nb or V |

|||

|

Grade 11 |

A |

STKM 11A |

0.12 max. |

0.35 max. |

0.60 max. |

0.040 max. |

0.040 max. |

- |

|

Grade 12 |

A |

STKM 12A |

0.20 max. |

0.35 max. |

0.6 max. |

0.04 max. |

0.04 max. |

|

|

B |

STKM 12B |

|||||||

|

C |

STKM 12C |

|||||||

|

Grade 13 |

A |

STKM 13A |

0.25 max. |

0.35 max. |

0.30~0.90 |

0.040 max. |

0.040 max. |

- |

|

B |

STKM 13B |

|||||||

|

C |

STKM 13C |

|||||||

|

Grade 14 |

A |

STKM 14A |

0.30 max. |

0.35 max. |

0.30~1.00 |

0.040 max. |

0.040 max. |

- |

|

B |

STKM 14B |

|||||||

|

C |

STKM 14C |

|||||||

|

Grade 15 |

A |

STKM 15A |

0.25~0.35 |

0.35 max. |

0.30~1.00 |

0.040 max. |

0.040 max. |

- |

|

C |

STKM 15C |

|||||||

|

Grade 16 |

A |

STKM 16A |

0.35~0.45 |

0.40 max. |

0.40~1.00 |

0.040 max. |

0.040 max. |

- |

|

C |

STKM 16C |

|||||||

|

Grade 17 |

A |

STKM 17A |

0.45~0.55 |

0.40 max. |

0.40~1.00 |

0.040 max. |

0.040 max. |

- |

|

C |

STKM 17C |

|||||||

|

Grade 18 |

A |

STKM 18A |

0.18 max. |

0.55 max. |

1.50 max. |

0.040 max. |

0.040 max. |

- |

|

B |

STKM 18B |

|||||||

|

C |

STKM 18C |

|||||||

|

Grade 19 |

A |

STKM 19A |

0.25 max. |

0.55 max. |

1.50 max. |

0.040 max. |

0.040 max. |

- |

|

C |

STKM 19C |

|||||||

|

Grade 20 |

A |

STKM 20A |

0.25 max. |

0.55 max. |

1.60 max. |

0.040 max. |

0.040 max. |

0.15 max |

Mechanical Properties

|

Steel Grade |

Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation(%) | |

|

Name |

No. |

ReH (min) | Rm(min) |

A(min) |

|

STKM 11A |

|

_ |

290 |

35 |

|

STKM 12A |

|

175 |

340 |

35 |

|

STKM 12B |

|

275 |

390 |

25 |

|

STKM 12C |

|

355 |

4700 |

20 |

|

STKM13A |

|

215 |

370 |

30 |

|

STKM 11B |

|

305 |

440 |

20 |

|

STKM11C |

|

380 |

510 |

15 |

Tolerance

|

SIZE |

Allowable tolerance |

Special Tolerance |

||

|

OD |

WT |

OD |

WT |

|

|

4mm-20mm |

±0.25mm |

<3mm ±0.3mm;

≥3mm ±10%

|

±0.05mm |

±0.05mm |

|

20mm-30mm |

±0.25mm |

±0.08mm |

±0.08mm |

|

|

31mm-40mm |

±0.25mm |

±0.10mm |

±0.08mm |

|

|

41mm-49mm |

±0.25mm |

±0.15mm |

±0.15mm |

|

|

50mm-80mm |

±0.5% |

±0.20mm |

±0.20mm |

|

|

81mm-120mm |

±0.5% |

±0.30mm |

±0.30mm |

|

Quality assurance

1. Strict according to JIS G3445 Standard or other standards.

2. Sample: Sample is free for test.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers' request

4.Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

Strengthen the inspection of products in each production stage, equipped with complete testing equipment: non-destructive eddy current testing, high pressure resistance testing machine, universal mechanical tensile testing machine, bending flattening flares testing machine, cleanliness analyzer, metal element analyzer, etc. Meet the mechanical properties of products, process performance test, provide a powerful guarantee for qualified products .