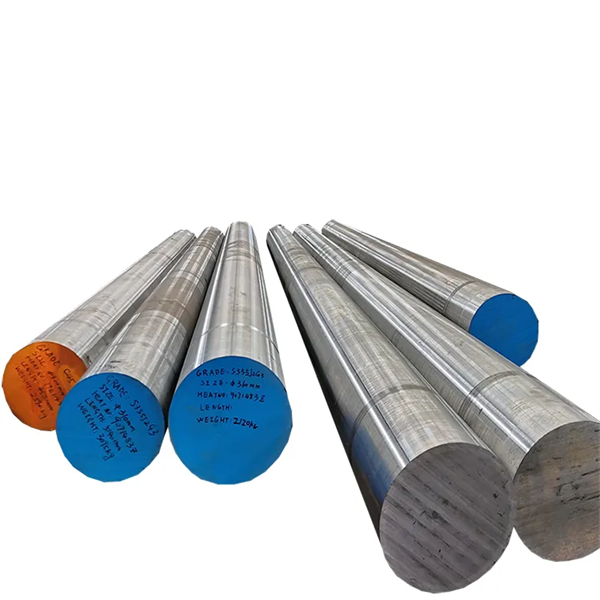

AISI 4130 SCM430 25crmo4 1.7218 Alloy Round Bar Engineering Steel

Specification

AISI 4130 steel bars are a low carbon alloy steel. They are belong to Chrome-Molly alloy that contains chromium and molybdenum as strengthening agents. AISI 4130 alloy steel is a medium carbon, low alloy steel in ASTM A29 standard. ASTM 4140 steel is also commonly referred to as a chromoly steel, or chrome moly steel, containing nominally 0.28-0.33% Carbon, 0.8-1.1% Chromium and 0.15-0.25% Molybdenum.

AISI 4130 round steel bar has good work ability, minimal processing deformation, and excellent fatigue resistance. It belongs to the category of medium to high harden ability steel. With the proper heat treatment it is also readily machined. Annealing ASTM 4130 alloy steel offers excellent ductility. AISI 4130 steel is usually supplied as round bar commonly in the hardened and tempered condition.

Parameters

| Product Name | AISI 4130 SCM430 25crmo4 1.7218 Alloy Round Bar | |

| Material | ASTM | 4130 |

| DIN | 25CrMo4/1.7218 | |

| GB | 30CrMo | |

| Standard | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm to1200mm | |

| Surface | Black painted, Bare, Polished, Chrome Plated | |

| Specifications | Round bar | 8mm~800mm |

| Angle bar | 3mm*20mm*20mm~12mm*800mm*800mm | |

| Square bar | 4mm*4mm~100mm*100mm | |

| Flat bar | 2*10mm~100*500mm | |

| Hexagonal | 4mm~800mm | |

| Process | Electric furnace melted, forged and annealed, round bar turned. | |

| Hardness: | HBS 217Max (Different from heat treatment) | |

| UT Test | SEP 1921/84/2 C/c class. | |

| Tolerance | Dia -0/+ 0~5mm, Thickness -0/+ 0~5mm, Width: -0/+ 0~10mm. | |

| Length | 2m,4m,5.8m,6m,11.8m,12m or as required. | |

| Package | Seaworthy Packing. | |

Equal Steel Grade

| Country | British | USA | Japan | BS |

| Standard | BS 970 | ASTM A29 | JIS G4105 | EN10083 |

| Grade | 708A25/708M25 | 4130 | SCM430 | 25CrMo4/1.7218 |

4130 steel chemical composition(%)

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

|

4130 |

0.28-0.33 |

0.15-0.35 |

0.4-0.6 |

0.035 |

0.04 |

0.8-1.1 |

0.15-0.25 |

/ |

|

25CrMo4 |

0.22-0.29 |

0.4 |

0.6-0.9 |

0.025 |

0.035 |

0.9-1.2 |

0.15-0.30 |

/ |

|

SCM430 |

0.28-0.33 |

0.15-0.35 |

0.6-0.85 |

0.03 |

0.03 |

0.9-1.2 |

0.15-0.30 |

/ |

4130 steel mechanical properties and Application

The mechanical properties mainly include tensile strength, yield strength, elongation, area or reduction, hardness, impact value, non-metalic inclusion etc. Different heat treatment, the mechanical properties will be different, such as normalized, tempered, QT.

4130 steel bar are used for commercial aircraft, aircraft engine mounts, military aircraft, automotive, machine tools, hydraulic tools, auto racing, aerospace, oil and gas industries as forged valve bodies and pumps, agricultural and defense industries etc.

Quality Assurance

1.Strict according to Requirements

2. Sample: Sample is available.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers' request

4.Certificate: IATF16949, ISO9001, SGS etc.

5. EN 10204 3.1 Certification